Seanamic Group, is expanding its global umbilicals business with a new Umbilical International facility in Glasgow. Initially it will offer umbilical repair and refurbishment for operators and contractors, in the lead up to full umbilical and cable manufacture.

Comprising Houston-based, Umbilicals International (UI) and Glasgow-

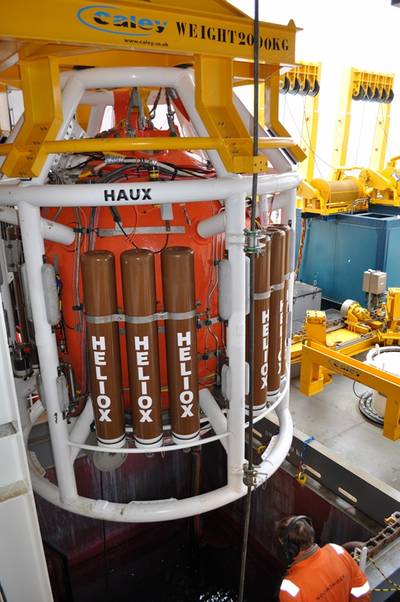

based Caley Ocean Systems, Seanamic supplies fully integrated umbilical and handling systems for well intervention, workover and BOP (MUX and direct Hydraulic), saturation diving and subsea habitats, ROVs and submersibles.

Umbilicals International designs and manufactures custom dynamic thermoplastic umbilicals and cables for the offshore and seismic industries. The new

UK facility will extend Umbilical International’s reach. And is consistent with the

Seanamic Group’s mission to offer surface to seabed equipment and services through its turnkey offerings, providing significant competitive and implementation benefits through synergy in design and manufacture across Group companies.

“The decision to expand the Umbilicals International business was prompted by the growing demand for dive umbilicals with a number of recent new contracts for our integrated dive handling systems,” notes Alasdair MacDonald, CEO, Seanamic Group.

The Renfrew-based umbilical facility will offer the complete line of Umbilical International’s diving range, as well as offering a full repair and testing service.

Going forward, umbilicals for subsea intervention systems will figure strongly at Umbilicals International (UK). Caley Ocean Systems is a leading supplier of IWOCS deployment systems. The combination of UI umbilical and Caley IWOCS deployment allows for a fully integrated system that avoids the kinds of interface issues which can often arise.

David Henderson, Business Development Manager, Seanamic noted: “Although many companies talk about designing and building an integrated system, only Seanamic is 100% in-house. Its value lies in the depth of design experience with umbilical and LARS systems. This translates into de-risking the project both commercially and technically, enabling customers to sidestep integration issues – reducing project risk and cost.