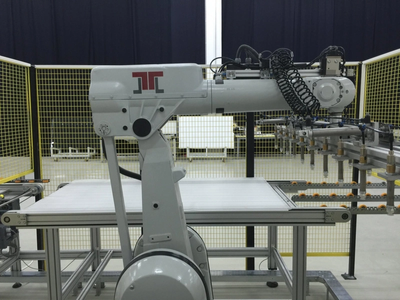

J.v.G. Thoma Introduces the Automatic Robot-LayUp 2020

Solar power specialists J.v.G. Thoma GmbH have completed a further automatic robot lay-up, the result of years of research and development by J.v.G. Thoma into the most efficient ways of harnessing renewable energy from the sun.

The company is renowned in the field of photovoltaic energy production for their innovative DESERT+ technology solutions, with solar panels designed for use in extreme climatic conditions. Now, with the introduction of the 120 MW, double string removal automatic robot lay-up designed to maximise efficiency in the manufacture of photovoltaic panels, you can increase throughput and be ready to compete in the flourishing renewable energy market.

Automated string placement improves accuracy and the robot’s soft touch and vacuum grippers allow gentle handling of the thin, fragile solar cell strings to reduce breakages to less than 0.1 percent. It allows for cell thicknesses of 0.25 mm down to 120 microns and a choice of 5”, 6” and 8” cell design and the module design is programmable (eg. number of cells per string). An optional camera allows cell breakages to be identified.

The robot lay-up machine is mounted on the ceiling of a portal: it takes the solar cell strings from a string box and also has the option of taking them straight from a stringer. It then positions the string into the alignment station. Next, the robot takes the string once more and its longitudinal position is measured by means of a photosensor. The robot then places the double string on the panel, turning every second string by 180° in order to achieve a + and - layup scheme. The string is aligned on two sides with an accuracy of greater than 0.1 mm.

The robot lay-up consists of a robustly constructed, compact station with an integral 6-axis robot.is designed for the manufacture of modules from 1.000 x 500 mm to 2.000 x 1.000 mm and can also be adapted for modules of bigger sizes to meet your specific requirements. It can be aligned either mechanically or by means of the optional vision system and can load directly from the stringer or from the string box; modules and glass are transferred by active and passive conveyors.

With global warming and the need for green electricity high on the agenda, now is the perfect time to invest in beautiful, renewable solar energy. With clear benefits of cost reduction and increased efficiency, the automated robot lay up is the ideal choice to help you achieve and surpass your renewable energy targets.