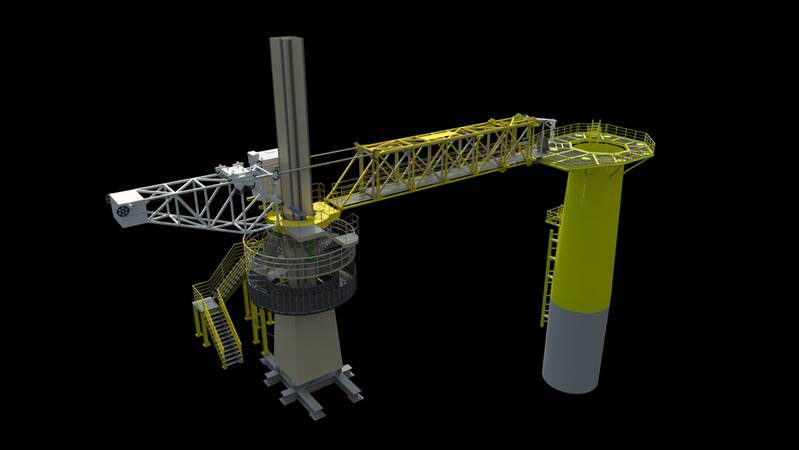

The Van Aalst Group has introduced a new motion compensated gangway system under the brand name Safeway.

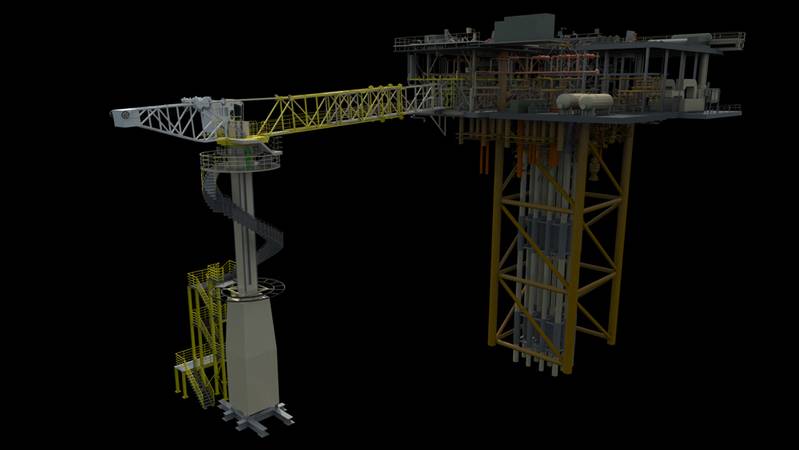

Developed and built in the Netherlands, the Safeway gangway bridge makes it possible for vessels to land at a broad range of offshore constructions, varying from small unmanned installations in the Southern North Sea to large offshore production units in the Northern North Sea.

Wijnand van Aalst, CEO of the Van Aalst Group, said, “With Safeway we are aiming to revolutionize the walk-to-work market, introducing a product which surpasses competition and will be very attractive for projects in both renewable and oil and gas markets.”

The first Safeway unit is currently under construction under Bureau Veritas class, with the first Safeway unit expected to be available for the rental market by the end of 2015.

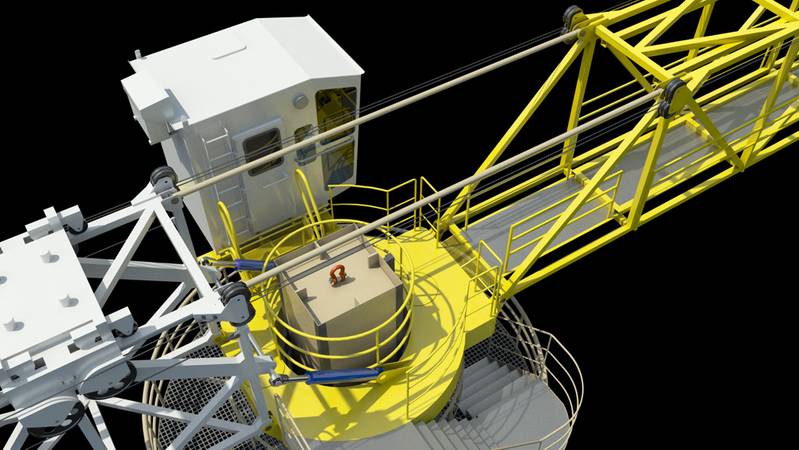

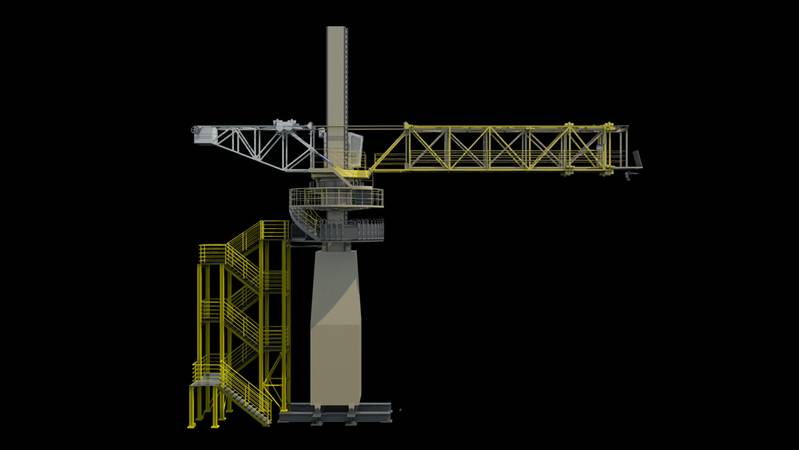

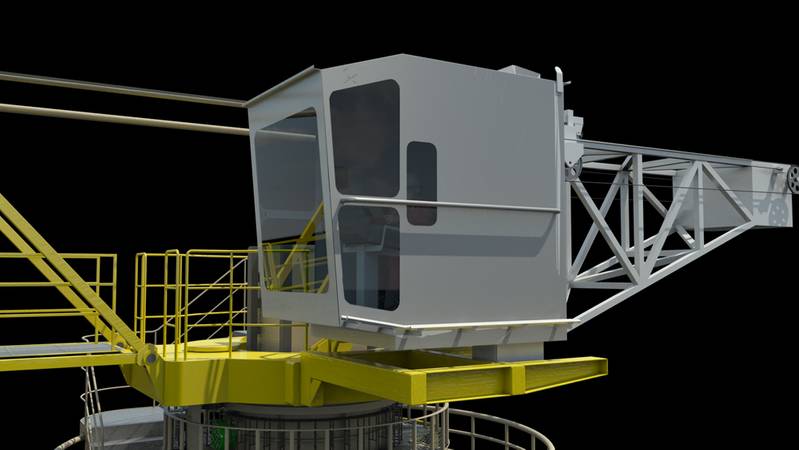

Safeway claims workability in up to 3.5-meter wave heights. Van Aalst’s planned introduction adds roll compensation, vertical height adjustment and a weight balanced boom construction to the gangway types now dominating the market. These innovations aim to increase the uptime of staff and equipment on any offshore installation. The added fourth motion actuator compensates for rolling, the vessel’s main motion.

The new gangway system targets improved safety for offshore workers. Van Aalst announces real redundancy by doubling all hydraulic cylinders. The possibility of a 10-meter vertical height adjustment enables the access arm to maintain a nearly horizontal position under most circumstances. This rules out unsafe uphill or downhill walking, further enhancing safety.

The new Safeway system is designed for easy handling and operating, reducing operational costs. The counterweight balanced boom construction has been an important feature in creating the desired simplicity. Safeway offers training facilities for the vessel’s crew on board or at Van Aalst office.