J+S Installs HV Splice for CNR Lyell MPBP

In what is reported to be a first in the North Sea, J+S Ltd, part of the Cohort Group, from its Aberdeen-based oil and gas division, has created an engineering solution to terminate HV connectors complete with pigtails onto an existing umbilical. The solution required replacement of a single three-phase connector with separate phase connections to each core.

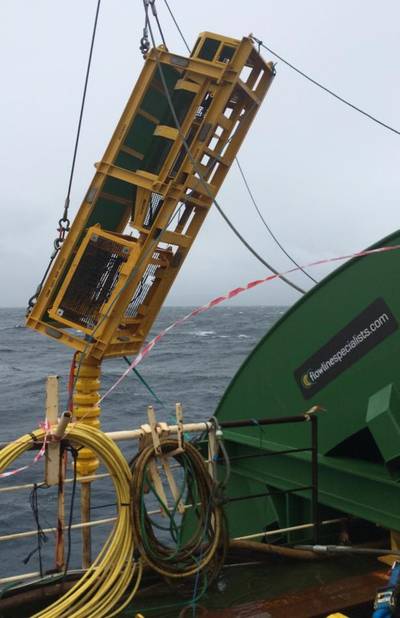

As most HV connectors are not field-installable and need to be pre-terminated to an umbilical, CNR asked J+S to deliver a solution which would enable an in-field assembly onto the existing umbilical. The J+S splice assembly design incorporated pressure-compensated splice housings for each phase and the HV connectors mounted within the frame, which protected the components during installation. The HV splices were designed to be fully re-terminated within the assembly envelope should this have been necessary at any stage during installation. The frame also provided removable covers, for access to the connectors for rapid connection following subsequent installation of the MPBP. The hugely costly alternative option for this solution would have been to install a new umbilical with pre-terminated connectors.

The bespoke design was fully assembled and installed offshore with the use of a J+S splice habitat, which is specifically designed for projects such as this.

A full range of electrical tests including High Voltage to Very Low Frequency tests was successfully carried out at critical stages of the offshore execution phase of the project. The splice is also designed to be used as a transition joint for different cable types.

As part of the design and qualification, a test splice was fully tested to design voltage under hydrostatic conditions to simulate subsea conditions. In addition, trial splice assemblies were carried out off-site prior to mobilization to simulate offshore conditions and ensure all team members were fully prepared to ensure the assembly was completed within a very tight schedule. The limited schedule was necessary due to restrictions on dynamic tensions on the umbilical whilst recovered on deck. All design and qualification activities were carried out in line with relevant sections of ISO13628. Norsok and DNV standards were also referenced where applicable.

Paul Hunter, CNR Subsea Controls TA said, “Having identified a fault with a pre-existing subsea wet mate connection; it became apparent that replacement of the connection would be necessary. In order to achieve a cost effective and economic solution, CNR approached J+S to provide an effective DSV surface based replacement of the existing wet mate connection, with a new assembly. J+S were instrumental in bringing what started life as a concept, into a working reality. They provided complete support throughout the project, ranging from onshore project management, design and manufacture of the solution, through to provision of a full offshore team to support installation, commissioning and assurances.”

Gavin Mann, CNR Underwater Superintendent added, “The J+S solution provided CNR with a novel and cost effective means of reinstating subsea power distribution reliability to a key item of underwater production equipment. One alternative might have been to replace the entire umbilical, but the topsides re-termination concept meant that we could integrate new equipment, with existing mature subsea infrastructure. This was a great example of where innovative technological solutions can be implemented to enhance the operating life of mature assets. The service provided by J+S throughout the project was excellent.”