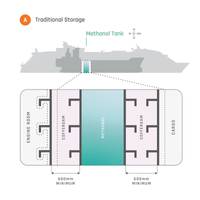

Exploring 'Future Fuels' - Methanol’s Superstorage Solution

Technical inquiries to SRC Group ramped up after it received Approval in Principle (AIP) for a concept which ‘reinvented methanol fuel storage’ on board ships. Delivering the answers has seen technical talk converting into project discussions ‘Green’ methanol has the ability to one day run vessels almost emission-free, and commercial shipping increasingly investigates. Derived today principally from natural gas, methanol is nonetheless available, relatively easy to handle and predictable. Lower carbon today, and potentially zero carbon tomorrow…

Steelwind Monopile Foundations for Parkwind's Baltic Sea Wind Farm

German construction company Steelwind will build monopile foundations for Parkwind's the Arcadis Ost 1 offshore wind farm in the Baltic Sea, offshore Germany.Under the contract, signed earlier this month, Steelwind will deliver 27 WTG and one OSS next-generation XXL-Monopile units.Arcadis Ost 1 Project Manager, Clément Helbig de Balzac from Parkwind commented: “We believe the signature of this agreement sends a strong positive message during a difficult COVID-19 context. The impact generated by this contract fits into EU’s Green Deal initiative…

Rolls-Royce to Provide Mooring System for Statoil's Njord A

Rolls-Royce has been chosen by Norway-based engineering and construction services firm Kvaerner to provide a mooring system for Norwegian oil and gas company Statoil’s oil platform, Njord A. Njord A is being upgraded by Kvaerner and Rolls-Royce has been chosen to provide an upgrade to its mooring system. The contract has a value of about £15 million ($19 mln). Njord A is a semisubmersible floating steel platform, with an integrated deck with drilling and processing facilities, as well as living quarters. It is normally located in the Njord oilfield, around 130 km northwest of the city Kristiansund and 30 km west of the Draugen field.

Increased Norwegian Content for Johan Sverdrup Platform

Today, Kvaerner and its sub-contractors cut the first steel plates for the utility- and living quarters (ULQ) topside for the Johan Sverdrup field. The topside construction starts on schedule and budget. The Johan Sverdrup development is being executed with a high degree of Norwegian value creation. Kvaerner's efforts to improve competitiveness have resulted in a large portion of the work for the ULQ platform to be executed in Norway. This gives Kvaerner and Norwegian subcontractors a steady activity and also a continued high number of apprentices.

Enseda Shipbuilding & Surviving the Petrobras Crisis

Enseada Shipbuilding was established to build deepwater drillships for Petrobras. Seventy percent of the company is owned by a consortium composed of Brazilian companies, Odebrecht (50 percent), OAS (25 percent), UTC (25 percent), with the remaining 30 percent belonging to Japanese shipbuilding giant, Kawasaki Heavy Industry (KHI). With all the Brazilian shareholders involved in the Car Wash “Lava Jato” operation, investigating corruption and embezzlement schemes with Petrobras, Kawasaki is a key partner, as is it not only responsible…

Massive LNG Absorber Shipped to Malaysia

Successful transport of 1,480t absorber for biggest LNG plant worldwide in Malaysia. 1,480 tons and a high center of gravity made the transport of an absorber from the Malysian Bintulu port to the Petronas LNG production site a challenging task. Due to the unprecedented tilting stability of the Scheuerle SPMT, the load was transported to the production site safely, despite difficult road conditions and turns. Limited ground resilience made the transport even trickier, a problem solved by side-by-side coupling of 2x24 axle lines of SPMT. At an overall freight length of 55,6 meters, turns become very narrow and precise steering is necessary.

North American Oil Trains Under Scrutiny

Sheriff Craig Apple assured a room of concerned citizens that county emergency crews were prepared to handle an oil-train accident involving three or four tank cars. Firefighters have been training to combat railcar fires with foam, and evacuation plans are detailed in a 500-page emergency response plan, Apple told residents in a May 12 address. Albany's tracks handle as much as a fourth of the oil pumped from North Dakota's booming Bakken Shale, or up to several 100-car trains per day, each carrying 70,000 barrels. It is one of several spots along North America's new oil-by-rail corridors where residents and officials are restless…