World’s Biggest Floating Wind Turbine Readies

The largest floating wind turbine in the world, an 8.4-megawatt (MW) ABS-classed offshore wind turbine, is about to be installed.ABS has classed the semi-submersible floating wind turbine is the first of three classed by ABS and designed by Principle Power housing MHI Vestas turbines that will make up for a total of 25 MWs of floating offshore wind power. The turbines are to be installed 20 km off the coast of Viana do Castello, Portugal.“ABS has supported innovation in offshore energy since 1958. This landmark installation underlines how we continue to support promising technology more than 60 years later,” said Christopher J.

Chevron Starts Gorgon Stage Two Drilling

Chevron Australia and the Gorgon joint venture participants have started the Gorgon Stage 2 drilling campaign off the northwest coast of Western Australia.Gorgon Stage Two is an expansion of the existing subsea gas gathering network on the Chevron-led Gorgon facility and is part of the project’s original development plan.Chevron Australia Managing Director Al Williams said the campaign will drill 11 additional wells in the Gorgon and Jansz-Io gas fields to maintain long-term natural gas supply to the 15.6 million tonnes per annum LNG and domestic gas plants on Barrow Island.The development…

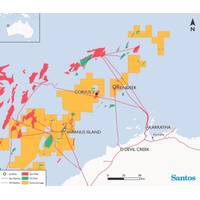

Santos Finds Gas Off Western Australia

Santos announced Tuesday it has confirmed significant gas resource in the Corvus-2 appraisal in the Carnarvon Basin, offshore Western Australia.Corvus-2 is located in 63 meters water depth, approximately 90 kilometers northwest of Dampier in Commonwealth waters within petroleum permit WA-45-R, in which Santos has a 100% interest.The well was drilled approximately 3 kilometers southwest of Corvus-1 (drilled in 2000) using the jack-up mobile offshore drilling unit Noble Tom Prosser and reached a total depth of 3,998 meters.

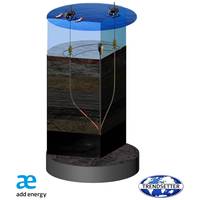

New Solution Simplifies Relief Well Operations

Energy consultancy provider Add Energy and subsea solutions provider Trendsetter Engineering have teamed up to develop the Relief Well Injection Spool (RWIS) Lite, designed to reduce the complexity of relief well operations on a global scale, when coupled with the original RWIS product. RWIS Lite is an exact structural replica of the original RWIS, which allows for duplicity in shared components. The original RWIS increases the flow capacity of a single relief well, which is a safer and less challenging option to drilling multiple relief wells during a subsea well blowout.

Cathelco MGPS for Latest Lamprell-built Jack-up

Cathelco will provide a marine growth prevention system (MGPS) for the latest in a series of jack-up drilling rigs to be built by Lamprell, the UAE based leading provider of fabrication, engineering and contracting services to the offshore and onshore oil and gas and renewable energy industries. This will be the ninth MGPS to be supplied to Lamprell for jack-up rigs constructed at its Hamriyah facility. The order was won by Cathelco Middle East FZC based in Sharjah which was set up in 2015 to provide sales and engineering support for customers throughout the region.

Wahlberg Headlines Film on Deepwater Horizon Tragedy

Nearly six years after the BP oil spill in the Gulf of Mexico, Hollywood takes its shot at recounting the tragedy with a film due this fall aiming to tell the story on the fatal blowout and its aftermath. The oil spill, one of the largest environmental disasters in global history, is depicted in the film Deepwater Horizon, named after the Transocean-operated semisubmersible Mobile Offshore Drilling Unit which suffered a catastrophic blowout and explosion on April 20, 2010, killing 11 workers and injuring 16 others, and leading to an 87-day-long oil spill in the Macondo Field about 40 miles off Louisiana.

FUGRO, Cross Group Awarded Multi Well GoM Contract

Fugro’s dynamically positioned multi-purpose drilling, well intervention and geotechnical vessel, Fugro Synergy, will showcase her capabilities on a multi well intervention campaign which recently started in the Gulf of Mexico. The campaign involves utilization of a top tensioned 6 5/8” riser and coiled tubing, and fieldwork for the contract is being undertaken jointly by the Cross Group Inc and Fugro, to employ the MODU (mobile offshore drilling unit). The vessel was designed and built specifically for well intervention services, and with her technical specification, Fugro Synergy complements MODU-based operations.

Fugro, Cross Group Bag Multi-Well Contract

Fugro’s dynamically positioned multi-purpose drilling, well intervention and geotechnical vessel, Fugro Synergy, is proving her capabilities on a multi well intervention campaign which recently started in the Gulf of Mexico. The well intervention campaign involves utilisation of a top tensioned 6 5/8” riser and coiled tubing, and fieldwork for the contract is being undertaken jointly by the Cross Group Inc and Fugro. It employs the expertise of both organisations, providing a safe, efficient and cost-effective field-proven MODU (mobile offshore drilling unit).

NDC Orders Newbuild Jackup Rig from Lamprell

Lamprell announced that National Drilling Company (NDC) has exercised one of its existing options and awarded a contract to Lamprell for the construction and delivery of a high specification jackup drilling rig. Lamprell has previously been awarded contracts by NDC for a series of eight rigs and this ninth rig will be of the same design. The LeTourneau-designed, Super 116E (Enhanced) Class mobile offshore drilling unit will be constructed at Lamprell’s facility in Hamriyah, United Arab Emirates (UAE), with a planned delivery in Q2 2017.

Major Oil Rig Contract for Harland and Wolff

In a multi-million pound boost to the Northern Ireland economy, Belfast ship builder Harland and Wolff has secured a contract to carry out major work on an oil rig. Dolphin Drilling Limited has awarded H&W the contract for the drydocking and Renewal/Special Periodic Survey of its Byford Dolphin Mobile Offshore Drilling Unit (MODU). H&W Director of ship and offshore unit repair, James Lappin said that this was a significant project for Harland and Wolff and for Northern Ireland. As well as employment opportunities, the supply chain within Northern Ireland will see significant activity in support of the project, he added.

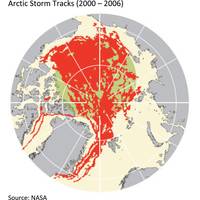

An Open Arctic and its Impact on Oil Drilling

William Cho, Head of MatthewsDaniel Weather, a division of the Bureau Veritas Group, explains why improvements in drilling technologies and weather monitoring systems have made offshore shelf drilling operations in the Arctic Circle increasingly attractive to upstream oil and gas companies and their investors. Rising crude oil prices motivate not only technological innovators to explore cheaper alternative energy sources, such as solar panels and wind turbines, but also upstream oil and gas companies to explore new oil reserves which had not otherwise been economical.

Drydocks World Completes Refurbishment of NDC’s Rig Al Ghallan

Drydocks World, the international service provider to the shipping, maritime, offshore, oil, gas and energy sectors, announced the completion of a major refurbishment carried out on National Drilling Company’s (NDC) Offshore Drilling Rig Al Ghallan. The project is part of a series of four rig repair and refurbishment projects signed with NDC in 2013. Before that, eight projects were completed. The numbers of projects carried out for NDC have progressively increased over the years. Drydocks World has a well-established reputation in the rig repair, refit and refurbishment segment.

Drydocks World Refurbishes NDC Rig

Drydocks World, the international service provider to the shipping, maritime, offshore, oil, gas and energy sectors, announced the completion of a major refurbishment carried out on National Drilling Company’s (NDC) Offshore Drilling Rig Al Ghallan. The project is part of a series of four rig repair and refurbishment projects signed with NDC in 2013. Before that, eight projects were completed. The numbers of projects carried out for NDC have progressively increased over the years. Drydocks World claims a well-established reputation in the rig repair, refit and refurbishment segment.

HSOG, Chowgule Create India Offshore Service Hub

International oil and gas service specialist HSOG has joined forces with the Chowgule Group, a multi-industrial International conglomerate, to offer a full range of maintenance and modification services to the offshore sector to service the international market. HSOG will now offer services to the world offshore market from the Chowgule Groups newly built Lavgan Dockyard, situated midway between Mumbai and Goa on the west coast of India. The $200m shipyard development has been completed over the last five years…

USCG Publishes Offshore Fire, Explosion Guidelines

As part of its continuing response to the Deepwater Horizon incident, the U.S. The Federal Register Friday published the U.S. Coast Guard's (USCG) notice of recommended interim voluntary guidelines concerning fire and explosion analyses for mobile offshore drilling units (MODUs) and manned fixed and floating offshore facilities engaged in activities on the U.S. outer continental shelf. This notice is part of the Coast Guard's continuing response to the explosion, fire and sinking of the MODU Deepwater Horizon in the Gulf of Mexico April 20, 2010.

Arctic Energy Exploration Efforts Heat Up

Oil and gas—and also mining—are the drivers today propelling Arctic maritime operations and the construction of new vessels able to operate in extreme latitudes. While the gas and oil resources can be recovered in the Arctic or far north and shipped to markets by sea or pipeline, the cost of doing must be balanced upon the global market price for those commodities. Ships and marine structures able to operate in the harsh conditions of the extreme latitudes require special designs and construction techniques.

USCG Releases Kulluk Grounding Investigation Report

The U.S. Coast Guard (USCG) Thursday released the report of investigation into the circumstances surrounding the grounding of the mobile offshore drilling unit Kulluk on the eastern coast of Sitkalidak Island, Alaska, Dec. 31, 2012. A series of events contributed to the causal factors that resulted in the grounding of the Kulluk, with the most significant factor being the inadequate assessment and management of risks associated with a complex vessel movement during the winter in the unique and challenging operating environment of Alaska. Among the safety recommendations issued in the report is the recommendation that the U.S.

Rig Decommissioned in Gomez Field

Acteon company InterMoor completed decommissioning operations of the Innovator platform in the Gulf of Mexico’s Gomez field, Mississippi Canyon Block 711. Conducted in water depths of 910 meters, the scope of work involved disconnecting 10 risers/umbilicals; disconnecting 12 mooring lines and then towing the Innovator to Ingleside, Texas. InterMoor said it developed special procedures for disconnection and towing, procured rigging and tow equipment for all vessels including the Anchor Handling Vessel (AHV), FPU and tug vessels, and provided personnel for the AHV and FPU throughout all phases of operations.

Economics of Dyneema-based Ropes

Traditionally thought an expensive alternative to traditional steel wire and conventional polyester-based synthetic ropes, offshore ropes and mooring systems made with Dyneema have been making inroads. End users such as ConocoPhillips, Shell and Petrobras are working with systems based on the high-strength, low-weight fiber of DSM Dyneema. Coupled with their durability and longevity, these rope systems are increasingly recognized for a variety of performance and user benefits that ultimately save on the bottom line. DSM Dyneema’s entry into the offshore industry more than 10 years ago met with more troubled waters initially.

Dyneema for Modu Mooring Lines In Brazil

Brazilian oil giant Petrobras has specified ultra strong, lightweight Dyneema fibers for a complete set of mooring ropes for a semi-submersible mobile offshore drilling unit (MODU). Headquartered in Rio de Janeiro, Petrobras has substantial interests in deepwater exploration. Petrobras specifically asked for the ropes to be made with SK78 grade of UHMWPE (ultra high molecular weight polyethylene) fibers from DSM Dyneema for its high strength at low weight properties. SK78 grade fiber was developed specifically for this type of mooring application and although it has a proven track record of success in Asia…