Wood Group Completes Work on MWCC Vessels

Wood Group Mustang has completed engineering services for the two Marine Well Containment Company (MWCC) vessels that can be deployed in the event of a deepwater well control incident in the US Gulf of Mexico. Services provided included the follow-on design engineering, on-site engineering, integration and testing of systems and components from multiple vendors, field engineering support, and management of US regulatory review. Other work, including spares procurement, is ongoing.

NOIA: Safety is First Priority Offshore

National Ocean Industries Association (NOIA) president Randall Luthi joined American Petroleum Institute (API) president and CEO Jack Gerard and International Association of Drilling Contractors (IADC) president and CEO Stephen Coleville this morning to discuss improvements in offshore safety since the Macondo Well accident five years ago. Luthi highlighted the importance of offshore safety, addressing many of the safety enhancements and industry measures that have been adopted since April 20, 2010.

Aker's Capping Technology to Limit Drilling Risks

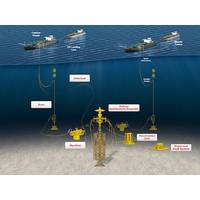

Aker Solutions delivered the key subsea component for the system being developed by Marine Well Containment Company to limit environmental risks from oil and gas production in the U.S. Gulf of Mexico. The Subsea Containment Assembly, or SCA, is designed to contain a well-control incident by connecting and creating a seal to prevent oil leaks. It can also be used in a cap-and-flow plan to direct fluid to vessels on the surface. The technology works under pressures as high as 15,000 psi.

Pre-production Inspection Aboard First of its Kind FPSO

This week a team of BSEE engineers and inspectors conducted a safety inspection of the first FPSO (floating production storage and offloading) vessel designed and built for containment use in the Gulf of Mexico. The pre-production inspection is one of the necessary steps to clear the Eagle Texas vessel for containment use in standard production operations or in emergency situations that require containment. The eight-member inspection group, led by Ronald Washington of the Houma District…

MWCC Completes GoM Shore Base Locations

Marine Well Containment Company (MWCC) today announced the completion of two new shore base locations to house its well containment equipment available for use in the U.S. Gulf of Mexico. In addition, this year marks the three-year anniversary of MWCC’s Interim Containment System (ICS) becoming available for use in the deepwater Gulf of Mexico. To date, more than 150 permits have been approved citing MWCC’s system. MWCC said it is committed to improving its equipment and response readiness in order to keep pace with its member company needs in the U.S. Gulf of Mexico.

Second Modular Capture Vessel for US Operation

Drydocks World announced the completion and delivery of Eagle Louisiana, the second of two Modular Capture Vessels (MCV) for the U.S. The first MCV, Eagle Texas, sailed away from Drydocks World’s yard in August last year. The vessels are the world’s first MCVs. Drydocks World converted the AFRAmax tanker for AET, a global leader in petroleum shipping, which has a 20-year agreement with Marine Well Containment Company (MWCC) for the operation of the MCVs. Ten world-renowned companies form MWCC: ExxonMobil…

Solar Solve Secures Contract for Marine Capture Vessel

South Shields based Solar Solve Marine received an order for Solasolv anti-glare, heat rejecting roller screens for the navigation bridge windows of a Marine Capture Vessel (MCV) which is being converted at Drydocks World in Dubai. Solasolv screens are installed at the windows of ships, rigs and cranes of all types and sizes worldwide. They reject up to 87% of heat and up to 93% of glare from the sun. Solar Solve claims that with its product eye-strain is reduced, ensuring computer displays are easier to read, and a clear outward view is maintained for safer operations.