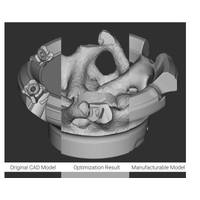

The Case for 3D Printing Downhole Tools

Advanced design software supports growth of additive manufacturing applications in the oil and gas industryAdditive manufacturing (AM, aka 3D printing) is beginning to impact product-development strategies in the oil and gas industry just as it already has in many other industries—by shifting the production paradigm in unexpected ways.Particularly in the case of downhole tools, overall tool size is compatible with the range of part dimensions that today’s AM systems are capable of manufacturing. Consider a common piece of equipment on any oil and gas rig: the tricone drill bit.

ExxonMobil, IBM Partner on Quantum Computing

Oil supermajor ExxonMobil announced Tuesday it has signed a partnership agreement with technology giant IBM to advance the potential use of quantum computing in developing next-generation energy and manufacturing technologies.The agreement sees ExxonMobil become the first energy company to join the IBM Q Network, a worldwide community of Fortune 500 companies, startups, academic institutions and national research labs working to advance quantum computing and explore practical applications for…

Aker Solutions to Supply Umbilicals for Liuhua FPSO

Aker Solutions said it has been contracted to deliver power umbilical systems to China National Offshore Oil Corporation's (CNOOC) Liuhua oil fields in the South China Sea, off Hong Kong.The order, which is said to be worth more than NOK 350 million ($36.6 million), was booked in the third quarter of 2018. The work scope includes more than 35 kilometers of dynamic and static power umbilicals for the Liuhua 16-2, 20-2 and 21-2 fields, linking the subsea development to a new floating production…

New RINA Guidelines for Additive Manufacturing

RINA, a specialist in additive manufacturing, has announced the release of its 'Guidelines for the certification of metallic products made by additive manufacturing', for the oil and gas industry.The use of additive manufacturing (or 3D printing) is expanding rapidly, especially as technology now enables the production of larger components and products to meet different mechanical or physical-chemical needs. The new guidelines from RINA will enable companies in the oil and gas industry to ensure every step of the additive manufacturing process is repeatable, documented and can be verified by a third party.

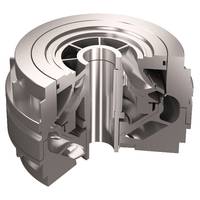

New HT/HP Subsea Valve Coating Developed and Deployed

An international collaboration between Hardide Coatings and Master Flo Valve Inc (MFV) has developed a new solution to protect high temperature, high pressure (HT/HP) subsea choke valves. The valves are the first of their kind to feature the Hardide-T coating, which can be applied to choke valve stems so they can withstand temperatures up to 400°F and pressures of 20,000 psi. Canada-headquartered MFV found that alternative hard coatings previously applied to the stem assembly were not rated to sufficiently high temperatures.

Borets Completes US Applications of WR2 Systems

Electric submersible pump (ESP) systems engineering, manufacturing, sales and service firm Borets has completed eight North American applications of its Wide Range Wear Resistant (WR2) pump system. The WR2 system is suited for hash well conditions and has the ability to handle a wide range of production, abrasives and gas with the goal of extending run life and minimizing well interventions, Borets said. The initial North American installation was completed on May 15, 2015, in a North West Oklahoma well designed to test the pump’s ability to handle a wide range of flow…

Trelleborg Tackles Lower Costs at SPE Offshore Europe

The sharp fall in oil prices has resulted in intensified competition within the offshore oil and gas industry and the prevailing market situation confirms a continued uncertainty ahead. The market was quick to reevaluate its processes and budgets, redirecting its primary focus to cutting costs, adding value and increasing efficiency. Fredrik Meuller, Business Area President, Trelleborg Offshore and Construction, said, “The natural reaction when the barrel price falls is for operators to cut costs wherever possible.

Prison Labor Keeps Solar Manufacturing at Home

One of the largest companies to manufacture solar panels in the United States uses a surprising resource to keep costs low and compete against producers from China: prison labor. Suniva Inc, a Georgia-based solar cell and panel maker that is backed by Goldman Sachs Group Inc, farms out a small portion of its manufacturing to federal inmates as part of a longstanding government program intended to prepare them for life after prison. Suniva does not actively publicize its work with the prisons…

Operational Excellence Becomes Oil Industry Watchword (again)

Cost-cutting is set to remain the main focus for the oil industry for at least the next two years as petroleum producers adjust to an environment of much lower prices. If the boom was characterised by an emphasis on ambitious and complex engineering and technology projects, the downturn has brought a renewed focus on simplification and efficiency. It marks a return to what was called "operational excellence" during the long years of low oil prices in the 1990s. Operational excellence is about more than just short-term expenditure reduction.

NAO, Vard Push Back PSV Deliveries

Nordic American Offshore Ltd. (NAO) informs that it has agreed with the Norwegian based Vard Aukra shipyard to extend the delivery of two platform supply vessel (PSV) newbuildings, originally scheduled to be delivered in mid-2015. Under the new agreement, the ships are scheduled to be delivered during the first quarter of 2016 when NAO will take ownership. The vessels are fully financed and the manufacturing process is developing satisfactorily, NAO said.

Hess Mirrors Toyota Manufacturing Process

Oil producer Hess Corp has turned to a manufacturing process developed by automaker Toyota Motor Corp to cut costs and boost production as crude oil prices lag. Deploying a process called Lean manufacturing, and used by only a handful of other oil producers, the move has shaved roughly $400,000 off the cost of each North Dakota well in the past eight months, a savings that comes even as Hess adds more sand and frac stages on each well. It has also sharply cut the time needed to drill a new well.

Technip Wins Contract for industrial Gas Complex in Kochi, India

Technip was awarded by Air Products a contract to provide project management, as well as engineering, procurement and construction management (EPCM) services for a new industrial gas complex for Bharat Petroleum Corporation Limited – Kochi Refinery (BPCL-KR) located in the state of Kerala, India. Being built on a “Build-Own-Operate” basis (BOO), the industrial gas complex of Air Products is designed to cater to the requirement of industrial gases (Hydrogen, Nitrogen and Oxygen) of BPCL-KR for its Integrated Refinery Expansion Project (IREP)…

Chevron’s Pascagoula Refinery Starts Production

Chevron Corporation subsidiary Chevron U.S.A. Inc. announced that it has begun commercial production of premium base oils from a newly constructed manufacturing facility at the company's Pascagoula refinery. Base oils produced at Pascagoula will add to capacity from the company's refinery in Richmond, California and a joint venture facility in Yeosu, Korea, approximately doubling Chevron's production capacity and positioning it to be the world's largest producer of premium base oil. "Lubricants are a high growth business supporting economic development worldwide…