Jan De Nul Orders Floating Installation Vessel

Luxembourg-based Jan De Nul has ordered a second mega offshore installation vessel, Les Alizés, from the CMHI Haimen shipyard in China.Together with the Voltaire, the new floating installation crane vessel will be in a super-size class of its own, capable of building the newest generation of offshore wind farms.Les Alizés, that will be ready in 2022, is equipped with a crane having a lifting capacity of 5,000 tons and equally impressive lifting heights.

Jan De Nul orders Offshore Installation Vessel

Six months after the offshore installation vessel Voltaire, Jan De Nul Group orders Les Alizés, a floating installation crane vessel from the CMHI Haimen shipyard in China.Together with the Voltaire, this new vessel will be in a super-size class of its own, capable of building the newest generation of offshore wind farms. Les Alizés, that will be ready in 2022, is equipped with a crane having a lifting capacity of 5,000 tons and equally impressive lifting heights.

Kawasaki Wins AiP for LNG Floating Power Plant

Japanese manufacturer of transportation equipment and machinery announced that it has obtained Approval in Principle (AiP) for its liquefied natural gas (LNG) floating power plant equipped with its own gas turbine (combined cycle power plant (CCPP) model).This approval was obtained from world-leading ship classification organization DNV GL based on its latest “Gas Power Plant” rules, which were introduced in 2018.An LNG floating power plant is an integrated system in which LNG fuel tanks…

Danos Awarded Major Permian Contract

Danos has been awarded a significant contract across multiple services lines with a Texas-based, independent exploration and production company. The project will leverage Danos’ Amelia Integrated Services Complex to fabricate piping and structural components which will then be shipped to the installation site in Midland, Texas, for assembly and construction of a central tank battery.“With this project, we have an opportunity to provide a turnkey solution for a valued customer,” said owner Eric Danos.

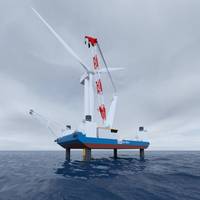

SEA-3250-LT: Innovation in Offshore Wind Installations

GustoMSC is targeting the burgeoning U.S. offshore wind energy market with an innovative jack-up design that it claims will help to reduce risk and increase efficiency when installing units offshore: the SEA-3250-LT installation jack-up. Designed to be a safe, stable and solid platform to lift these heavy, delicate components to heights of more than 426 ft (130 m) in an area where technicians are performing assembly tasks at the same time. GustoMSC plays a pioneering role in the offshore wind installation market…

Heavy Lift: Cryogenic Heat Exchanger Installed

The second of three planned Main Cryogenic Heat Exchanger (MCHE) installations at a large liquefaction project in southwest Louisiana marked a milestone for the U.S. Gulf Coast project. Heavy lift and transportation services provider Mammoet used 40 axle-lines of Self-Propelled Modular Transporters (SPMTs) to transport the equipment to the installation site. The lift of the MCHE, which is 150 feet long, 16 feet in diameter and weighs a total of 576,000 lbs.

LQP-1 Topside Transport Completed

Transportation of the latest facility for the Vladimir Filanovsky oil field – the topside section of the living quarters platform (LQP-1) – has been successfully completed. The facility was built and prepared for transportation under the survey of Russian Maritime Register of Shipping (RS) at the Shipbuilding Yard Krasnye Barrikady, JSC in the Astrakhan region, Russia. The facility was transported on the Yury Kuvykin transport-assembly barge from the port of Astrakhan (Shipbuilding Yard Krasnye Barrikady…

Float-over Installation at the Vladimir Filanovsky Field

The transportation of the topside section of a central processing platform (CPP) site at the Vladimir Filanovsky field, its installation site, began this week on June 25. This transport, surveyed by Russian Maritime Register of Shipping (RS) launched at the Globalstroy-Engineering (GSE) assembly site in Ilyinka, Astrakhan region. The CPP topside section is part of the infrastructure at the Vladimir Filanovsky field, located in the Russian sector of the Caspian Sea on Severniy license zone territory.