Mercedes reduces the environmental footprint of EVs with low-carbon aluminum

Executives at Mercedes-Benz said that aluminium made from renewable energy and recycling helps the luxury automaker reduce CO2 emissions when producing its new electric vehicle line. This is part of an overall effort to decarbonise their operations. Mercedes' new CLA electric model is made from low-carbon aluminum, which was developed in partnership by Norsk Hydro and Norwegian metals manufacturer Norsk Hydro. Executives of both companies stated that the collaboration was an example of how manufacturers of premium consumer goods may pay more for raw materials to achieve a profile with a higher environmental impact.

BHP: Australian green iron is too expensive despite joint China agreement

BHP, a major miner, said that it would be too expensive for Australia to develop a "green-iron" industry. This is despite the fact that Australia and China had agreed to work together this week to decarbonise steel supply chains, which are responsible for almost a tenth percent of global emissions. BHP Australia's Geraldine Slattery said the costs of producing low-carbon steel products "just don't stack up" when she attended a session in China on green steel this week with Prime Minister Anthony Albanese and Australian miners, as well as Chinese steelmakers.

BHP: It is too expensive to build an Australian green iron industry, as PM calls for China collaboration

BHP, a major miner in Australia, has stated that it would be too expensive for Australia to develop a "green-iron" industry. This comes after Australia and China decided to work together this week to decarbonise steel supply chains. These are responsible for almost a 10th of all global emissions. BHP Australia's Geraldine Slattery said the costs of producing low-carbon steel products "just don't stack up" when she attended a business round table with Australian and Chinese leaders this week in China. Slattery…

Sources say that India's steel minister is seeking $1.7 billion from the budget to assist mills reduce emissions.

Two government sources who are directly involved in the matter said that the Indian steel ministry requested 150 billion rupees (1,74 billion dollars) to be allocated to the budget as incentives for mills to produce low carbon steel. Nirmala Sitharaman, Finance Minister, will present the federal Budget for 2025-2026 on February 1. India, which is the second-largest steel producer in the world after China, is working on a policy to decarbonise the production of the alloy. This effort forms part of an overall push for reducing greenhouse gas emissions as part of a net-zero goal set by Narendra Modi.

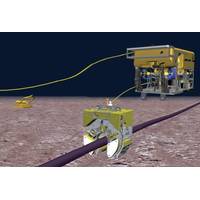

Subsea Umbilicals Demand Hit by COVID-19

Analysts from Norway's Rystad Energy expect that the global oil and gas investment cuts will severely hit demand for subsea equipment, with demand for subsea umbilicals expected to fall by 32%.Rystad sees just 713 kilometers (km) of lines ordered in 2020, down from 1,041 km last year."Umbilical demand will not match or exceed 2019 levels until after 2023, our forecasts show, despite definite cost savings in materials. To put these numbers into context, before the pandemic demand for umbilicals was due to slightly decrease this year compared to 2019…

Jotun's New High Temp Coatings

Jotun is setting a new standard in coatings for hydrocarbon processing facilities with the launch of Jotatemp 1000 Ceramic, an innovative coating solution that can be applied to surfaces with temperatures reaching 1000ºC. This increased tolerance (previous advanced coatings offered a maximum endurance of 650ºC) is tailor-made for an industry where a shift to higher temperature operations is helping optimize processing and productivity. Jotun has established itself as a global leader in innovative protective coating solutions…

Technip Bags Woodside's Subsea Contract

Technip has been awarded a large(1) subsea contract by Woodside to support the development of the Greater Enfield Project offshore Western Australia, at a water depth comprised between 340 and 850 meters. - multi-phase pump system (transport and installation). Technip’s operating center in Perth, Australia will execute the contract with support from Technip’s Asia Pacific Subsea Hub in the Kuala Lumpur office in Malaysia, and office in Chennai, India. - the umbilicals will be supplied by Technip Umbilicals’ facility located in Newcastle, UK.

Subsea 7 Bags Norwegian North Sea Contract

Subsea 7 S.A. announced it has been awarded a pipeline and construction contract worth approximately $300 million from Wintershall Norge AS for the Maria field development. The contract consists of engineering, procurement, construction and installation (EPCI) of 95 kilometers of rigid flowlines and associated structures to develop the Maria field located in the Norwegian Sea at a water depth of approximately 300 meters. Project management and engineering work will commence immediately at Subsea 7’s offices in Stavanger…

JIP Launched to Examine Polymer Lined Pipes

A joint industry project (JIP) has been launched between Swagelining Limited, Saudi Aramco and The Welding Institute (TWI) to conduct investigations into the use of polymer lining in carbon steel pipelines. The JIP will examine the extent of corrosion incurred in a polymer lined pipeline when subjected to a sour hydrocarbon fluid environment. Between the three parties, a total of £330,000 has been invested into the project, which commenced in October 2014 and is expected to last 30 months. Dr. Steve Brogden…

Saipem Bags Kashagan Contract

Italian oil service company Saipem said on Friday it had won a contract to lay replacement pipelines at the giant Kashagan field in Kazakhstan, worth around $1.8 billion. Last month sources with knowledge of the matter told Reuters Saipem was in pole position to win the pipeline contract which could be worth up to $2 billion. In a statement on Friday Saipem said the North Caspian Operating Company had awarded Saipem the contract for the construction of two 95-kilometre pipelines. "The construction will be completed by the end of 2016," it said.

Polymer Technology Developments Present Opportunities

New advances in polymer lining systems are emerging as a credible and cost effective alternative to traditional corrosion resistant alloys (CRA), thanks to recent developments from Swagelining Limited. Over the last four years, Swagelining, a designer and installer of polymer linings for pipeline and riser systems, has been working with a number of oil companies, resin producers, global subsea EPC contractors, universities and niche manufacturers to develop and qualify an integrated polymer lining system that is expected to expand the service application window for polymer lining.

New Pipelines to Boost Kashagan Project Costs

Kashagan, the world's most expensive oil project, will have to spend another up to $3.6 billion to replace leaking oil and gas pipelines, which also could delay the restart of production, the Kazakh energy ministry said. Production at the Kashagan reservoir, the world's biggest oil find in recent times, started in September last year but was halted just a few weeks later after the discovery of gas leaks in the $50 billion project's pipeline network. Replacing the pipelines at the oilfield, which lies in the Caspian Sea off western Kazakhstan…

Wachs Subsea Answers the Call for Chevron

When looking for an emergency preparedness system for the Gulf of Mexico and elsewhere, Chevron enlisted the aid of Wachs Subsea to create an automated pipeline repair system using Wachs Combination Prep Tool (CPT) as the key operational component. The design parameters included a machine that was lightweight so it could be transported by air, operational at depths to 3,000 meters (10,000 feet), and configured to perform all the pipeline machining tasks associated with installing a sleeved replacement pipe section (or spool) in a single deployment.

Technip Awarded Subsea Contract in the Gulf of Mexico

Technip was awarded by Deep Gulf Energy II LLC a lump sum contract for the development of the Kodiak field, located in Mississippi Canyon Blocks 727 and 771, in the Gulf of Mexico, at water depths ranging from 1,472 meters to 1,710 meters. The project consists of a subsea tie-back to the Devils Tower Truss Spar located in Mississippi Canyon Block 773. To withstand Kodiak field’s high temperature and pressure as well as extremely corrosive production fluids, the pipeline will be of a bi-metallic construction, lined with corrosion resistant alloy(1).