Damen Delivers Custom-Made Offshore Winches to Fugro

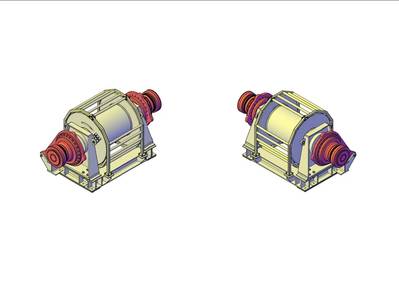

Damen Maaskant Shipyards, part of Damen Shipyards Group, has delivered two dedicated offshore winches to Fugro.

The Dutch shipyard was responsible for the design, engineering and manufacturing of the two winches from its base in Stellendam in the Netherlands. Maaskant also worked very closely with Bosch Rexroth, which delivered the hydraulic drive system.

Classified by DNV GL, the two winches – a constant tension winch with an own weight of 2,000 kg and a drilling winch (own weight 3,500 kg) - have to meet the very highest offshore standards.

Antoine de Jonge, Project Engineer at Maaskant, comments: “The use of these types of hydraulic drives for this kind of winch design is different from the standard drives. This type of constant tension winch particularly, is relatively small but still powerful and user-friendly. There are not many companies making them to these specifications. The drilling winch, on the other hand, is a heavy hoisting winch with small dimensions, which has been entirely manufactured under Class for Offshore Standards. During the design and throughout the project our Winch Department worked very closely with Fugro’s technical superintendent.”

Winch characteristics

The drilling winch - type M1-H2-135 - has a storage capacity of 230 m of steel wire with a diameter of 26 mm. It has a hauling and holding force of 13.5 tonnes but if required, this can be adjusted up to 18.5 tonnes, which is available on all layers of the wire. The range of hauling and veering speed is from 26 m/min. up to 136 m/min.

The hard tie winch - type M1-H1-60 - has a drum storage capacity of 40 m of steel wire with a diameter of 22 mm. The winch has a Constant Tension Mode, which has precision accuracy, and a CT force between 0.2 tonnes and 2 tonnes. As well as the CT Mode, there is also a special Slipping Mode with an adjustable holding force of 7.5 tonnes available. Maximum speed during the CT Mode is 290 m/min up to 500 m/min in the Slipping Mode.

The two winches will be installed on Fugro’s MV Bucentaur, a deepwater drilling ship, in April.