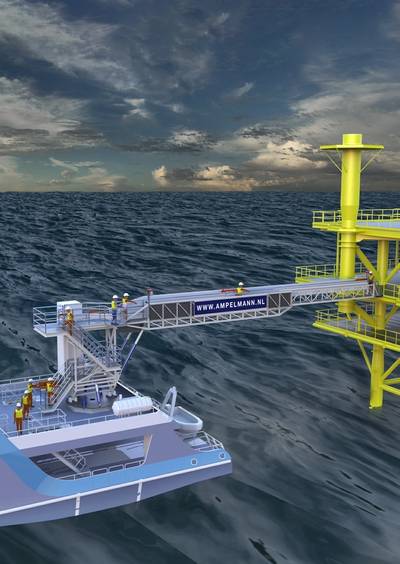

Dutch company Ampelmann says it has designed its latest motion compensation access system, the S-type, as a cost effective and safe option in the transportation of workers and luggage to and from offshore platforms.

The company, a provider of offshore access systems to the energy industry, is launching the new Walk-to-Work system as an alternative to using helicopters or baskets.

In total, the cost of using the system will be around 30 perceent cheaper than helicopters, the manufacturer said. The S-type incorporates a lightweight system that uses a low amount of energy to operate.

Aimed at the global oil and gas market where volume of crew is high and the sea state can be severe, the S-type can continuously transfer 50 people and luggage in five minutes in significant wave heights of up to three to four meters. The S-type design includes a separate luggage belt, can be tailored for installation to individual vessels and is expected to be a particularly attractive option on current or new build fast or light-weight medium-sized vessels; such as mono-hulls, catamarans and trimarans.

Gerbrand Marbus, Crew Change Market Manager, said, “The S-type can easily transfer more people at a time than helicopters and is a safe alternative. As the industry continues to look for ways to work more effectively, we have listened to operators requests and developed a system that should be an attractive option for companies as well as providing more comfortable transportation for their workforce.”

“In developing the S-type we worked closely with vessel designers to provide an integrated package that has a reduced footprint and is lighter than comparable systems,” Marbus continued. “With this integrated package, different clients can share logistics and see walk to work as an offshore bus service reducing their crew transportation costs by 30 to 40 percent. The technology used in the transportation system will place the S-type as a leader in the Walk to Work crew change market.”

The S-type provides a wide operational range thanks to its 360 degrees access and is a lightweight system with low energy consumption. In comparison, it is approximately half the weight and uses 50 percent less energy than typical similar systems.

In addition, the S-type occupies a small deck space and can be fully integrated with its host vessel. It requires no alterations to the receiving platform.